COST-EFFECTIVE SOLUTIONS

Begin at a range of 50-75%

WARRANTY

4-year Full Service

DELIVERY

Multiple locations to provide tailored support.

Welcome to NNG Industries, Where innovation meets Excellence

With a focus on sustainability, we are committed to driving practices that not only increase efficiency but also reduce environmental impact. Imagine transforming your workspace into a hub of productivity where advanced systems effortlessly adapt to your evolving needs, ensuring not just precision but also profitability.

Our team of experts works tirelessly to create tailored strategies that empower you to excel in a competitive landscape, redefining what it means to be a leader in machining. Experience the difference with NNG Industries and unlock the true potential of your manufacturing capabilities.

UnExceptional Supportmatched Sales and Service

Discover our Exchange Core Program offering New, Used, or Rebuilt products tailored to your needs.

Trade with us to access a world of opportunities and enhance your business potential by leveraging our expertise and extensive network, ensuring you stay ahead of the competition while achieving your goals efficiently and effectively.-In: Upgrade with ease by trading in your old unit for a new or rebuilt one, saving money and reducing downtime.

Repair: Revitalize your worn chucks or actuators at half the replacement cost with our expert repair services for any size, manual, air or power chuck.

Parts: Our extensive inventory includes parts for new and obsolete chucks, such as collets, chuck jaws, draw tubes, and more.

Modifications: Customize your chucks to fit your exact needs or match existing tooling with our expert modifications.

Maintenance: Ensure constant clamping force, accuracy, and extended service life of your chucks with regular maintenance from NNG Industries. Rust, dust, chips, and coolant can increase friction and wear. Our maintenance services keep your chucks clean and functioning at peak performance.

Warranty: Enjoy peace of mind with our industry-leading warranty, offering coverage measured in years not months.

Exceptional Knowledge Across a Wide Range of Industries

We proudly serve diverse industries, delivering tailored solutions and expertise to meet their unique needs.

Our experience and capabilities span across a huge span of industries. We are experts in finding solutions for manufacturers dealing with the most challenging industrial challenges.

- Aerospace

- Automotive

- Bearing Manufacturers

- Ceramics

- Machine Tools

- Medical

- Military & Defense

- OCTG

- Petrochemical

- Production Manufacturing

- Including (any) Manufacturers

Unparalleled Expertise in Delivering Results

Are you experiencing challenges with your workholding device?

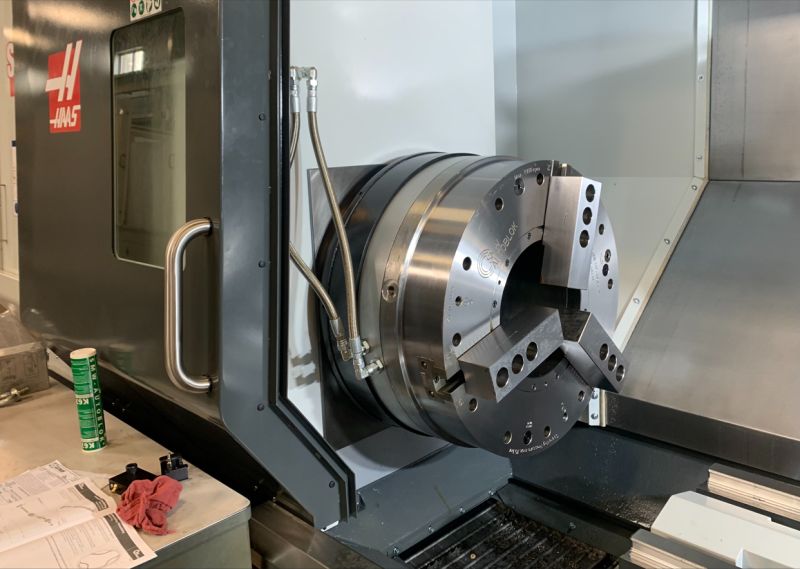

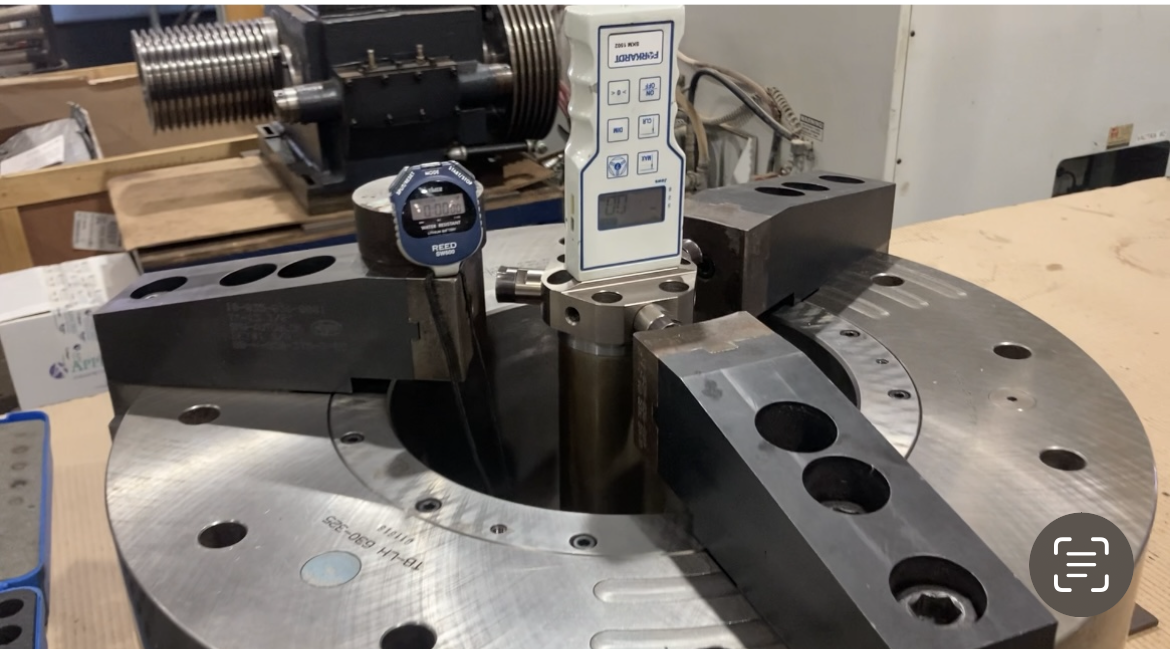

Workholding

Repair, sales, and exchange services.

At NNG Industries, we excel in providing advanced workholding solutions tailored to enhance productivity and precision in your machining processes. Our innovative designs ensure that your workpieces are held securely, allowing for consistent and accurate operations. Whether you require standard or custom fixtures, our team can develop workholding systems that meet your specific requirements, reducing setup times and increasing throughput. Trust NNG Industries to deliver robust and reliable workholding solutions that optimize your machining performance and boost your bottom line.

Clamping

Repair, sales, and exchange services.

NNG Industries offers a comprehensive range of clamping systems designed to provide maximum stability and reliability during machining. Our clamping solutions cater to various materials and applications, ensuring your workpieces are firmly secured for optimal machining accuracy. From manual to automated clamping systems, we have the expertise to enhance your operational efficiency and precision. Our advanced clamping technologies minimize the risk of workpiece movement, leading to superior quality results and increased productivity. Rely on NNG Industries for all your clamping needs to achieve consistent, high-quality outcomes.

Steady Rest

Repair, sales, and exchange services.

Our state-of-the-art steady rest systems at NNG Industries are engineered to provide exceptional support and stability for your workpieces during machining. By minimizing vibration and deflection, our steady rests ensure smooth and precise operations, enhancing both quality and efficiency. We offer a variety of adjustable and customizable steady rest options to accommodate different workpiece sizes and shapes. With NNG Industries, you can count on steady rest solutions that deliver optimal performance, reduce operational disruptions, and improve overall machining accuracy.

Live Tooling

Repair, sales, and exchange services.

Enhance the versatility and capability of your CNC machines with NNG Industries’ live tooling solutions. Live tooling enables you to perform multiple machining operations without repositioning the workpiece, saving valuable time and increasing operational efficiency. Our high-quality live tooling options are compatible with a wide range of machine tools, allowing you to expand your machining capabilities and achieve superior results. By incorporating live tooling into your operations, you can streamline processes, reduce cycle times, and enhance the overall productivity of your machining endeavors. Let NNG Industries help you unlock the full potential of your CNC machines with our advanced live tooling solutions.

NNG is a Master Repair Station recognized for excellence in servicing a wide range of leading manufacturers listed below:

AHD

ASI

Atlas

ATS

Autoblok

Ball

Bergman

Bison

BTC

Buck

Bullard

Cushman

Forkardt

Fuji

Flex-e-on

Gamet

Giddings & Lewis

Gisholt

Goss

Hardinge

Hitachi

Howa

ITW Workholding

Kalamazoo

Kametsu

Kitagawa

Logansport

Magnalock

Matsumoto

Mazak

Mori Seiki

NA Woodworth

New Britain

Nobel

Okuma

O.S. Walker

Pratt Burnerd

Powerhold

Rohm

Royal

Rotomors

Samchully

SCA

Schunk

Skinner SMW Systems

SP

SP Sheffer

Strong

Suburban

Technomors

Ward

Warner & Swasey

Woodworth

Yuasa

NNG specializes in the sale, repair, and exchange of all types and brands of power and manual lathe chucks and workholding devices, ensuring quality and reliability for your machining needs.

Air Chucks

Arbor Chucks

Ball Chucks

Boring Mill Chucks

Car Wheel Chucks

Centering Chucks

Collet Chucks

Combination Chucks

Compensating Chucks

Counter Centrifugal

Diaphragm Chucks

Draw Back Chucks

Gear Chucks

High Precision Chucks

Highspeed Chucks

Hydraulic Chucks

Indexing Chucks

Independent Jaw

Long Stroke Chucks

Magnetic Chucks

Mandrel Chucks

Multi Spindle Chucks

Power Wrench Chucks

Pull Back Chucks

Quick Change Chucks

Quick Jaw Change

Scroll Chucks

Self Centering Chucks

Self Contained Chucks

Special Chucks

Spring Chucks

Stationary Chucks

Thru-hole Chucks

Truck Wheel

VTL Chucks

Vertical turret lathe

VBM Chucks

Vertical Boring Mill

Wheel Lathe Chucks

Discover Our unmatched Capabilities

Here’s What Sets Us Apart From The Rest

The NNG Network - We're Everywhere So We Can Service You Anywhere!

(US, Canada & Mexico)

Discover the convenience of our multiple state of the art service locations across the United States, Canada, and Mexico. At NNG Industries, we prioritize accessibility and efficiency, ensuring that our clients can access our exceptional services with ease, no matter where they are located.

Emergency On-Call 24-7 Service

(Including Holidays)

Experience peace of mind with our emergency on-call 24/7 service, including holidays. At NNG Industries, we understand the urgency of unexpected machine failure issues and are committed to being there for our clients whenever and wherever they need us.

Large Savings - We’ll Beat Any Competitor or Major OEM

Unlock substantial savings with NNG Industries—we guarantee to beat any competitor or major OEM. Our commitment to providing the best value extends beyond exceptional service and quality products; we also ensure that our prices are the most competitive in the market. Trust us to deliver superior results without compromising on affordability, saving you money while maintaining uncompromised excellence in every aspect of our offerings.

Fast Precision Service Done Right the 1st Time

Experience fast, precise service done right the first time at NNG Industries. We understand the importance of efficiency and accuracy in CNC manufacturing, which is why we prioritize delivering exceptional results without compromise. Our skilled technicians and state-of-the-art facilities enable us to complete projects swiftly and accurately, ensuring that every job is done right from the outset.

Exchange Program = No Downtime

Eliminate downtime with our innovative exchange program at NNG Industries. Our exchange program allows you to quickly replace damaged machines with fully working ones during your repair, ensuring seamless operations without any interruptions. By participating in this program, you can avoid costly downtime and keep your production running smoothly. Experience the convenience and efficiency of our exchange program, designed to minimize disruptions and maximize productivity for your business.

Over 45 Years of Experience in Automation, and Liner Motion Technology

Benefit from 45 years of unparalleled experience and expertise at NNG Industries. With a rich history of innovation, precision, and customer satisfaction, we have established ourselves as leaders in the CNC industry. Our decades of experience enable us to deliver exceptional quality, reliability, and efficiency in every project we undertake, setting us apart as your trusted partner for all your CNC needs.

Extensive Library of Newer & Older Hard to Get Prints

Tap into our extensive library of both newer and older hard-to-get prints at NNG Industries. We understand the importance of having access to a diverse range of technical drawings and specifications, which is why we have curated a comprehensive collection that includes the latest designs as well as rare prints that may be challenging to obtain elsewhere.

Full Inspection Analysis Report

Experience transparency and thoroughness with our full inspection analysis report at NNG Industries. When you entrust your equipment to us, our dedicated team conducts a comprehensive inspection, leaving no detail unchecked. From disassembly and cleaning to detailed analysis and diagnosis, we provide a comprehensive report that outlines the condition of your equipment, identifies any issues or potential concerns, and offers tailored solutions for optimal performance.

4-Year Service Warranty

Rest assured with our industry-leading 4-year service warranty at NNG Industries. We stand behind our workmanship and the quality of our services, which is why we offer an extensive warranty period to our clients. With this warranty, you can have peace of mind knowing that any issues or concerns with the services we provide will be promptly addressed and resolved, ensuring long-term satisfaction and reliability. Trust NNG Industries for superior service backed by a commitment to excellence that lasts for years to come.

All Under One Roof:

Complete O.D./I.D. Grinding, 3rd 4th & 5th Axis Machining, Milling (Manual & CNC) Electrical Discharge Machining (EDM), Industrial Plating & Thermal Spraying, Injection Molding, Precision Welding, 3D Scanning and Printing.

Need Service Now? Ask about our same day service!

NNG is paving the way for a brighter future.

What our customers say

Excellent Service

Outstanding Service

Donec sit amet gravida mauris, vitae ornare sem. Cras dignissim est mollis ex vehicula, in iaculis arcu volutpat

David Wilcox

Professional Service

Amazing Work

Donec sit amet gravida mauris, vitae ornare sem. Cras dignissim est mollis ex vehicula, in iaculis arcu volutpat

Let’s Get Connected

Clamping

Clamping

Live Tooling

Live Tooling